Capabilities

Mechanical & Thermal Design

Our Engineers have experience in develop and perform both, mechanical and thermal design.

The experiences almost all the Codes:

- ASME VIII Div. 1 & 2

- ASME I

- EN 13445

- DET NORSKE VERITAS RULES FOR SHIP

- AD 2000

- BS 5500

- CODAP

- VSR

- VSG

- TEMA

- IBR

- GOST R

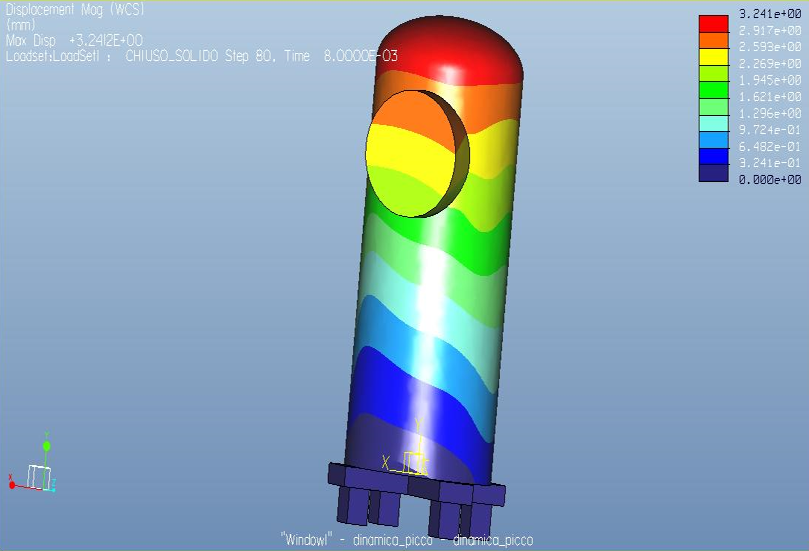

The design is developed in-house based on client’s specifications and international standard. We can also perform Three Dimensional Finite Elements Analysis (3D FEA) if required by Client.

Other than FEA, we can perform:

- Thermal and vibration rating (HTRI)

- Heat Exchanger & Vessel Fatigue Analysis with thermal and mechanical loads

- Local Stress Analysis

- Nozzles Loads Analysis according to WRC 107/97 and FEA

- Wind & Earthquake Analysis

- Lifting & Transportation Analysis

Manufacturing

Villa Scambiatori is well equipped to deliver equipment in all kind of materials from Carbon Steel to the most ferritic and austenitic – i.e. Duplex, Superduplex, copper & nickel alloys and Titanium.

All welders and welding procedures are qualified by Independent Testing Authorities, EPCs, End Users worldwide.

Overall Manufacturing Capabilities:

Welding:

- Manual (TIG and GMAW)

- Automatic (SAW)

- Weld Overlay (SAW and Electroslag)

- Stainless Steel all grades (Single and Double Layer)

- Nickel Based Alloys, All grades

- Monel

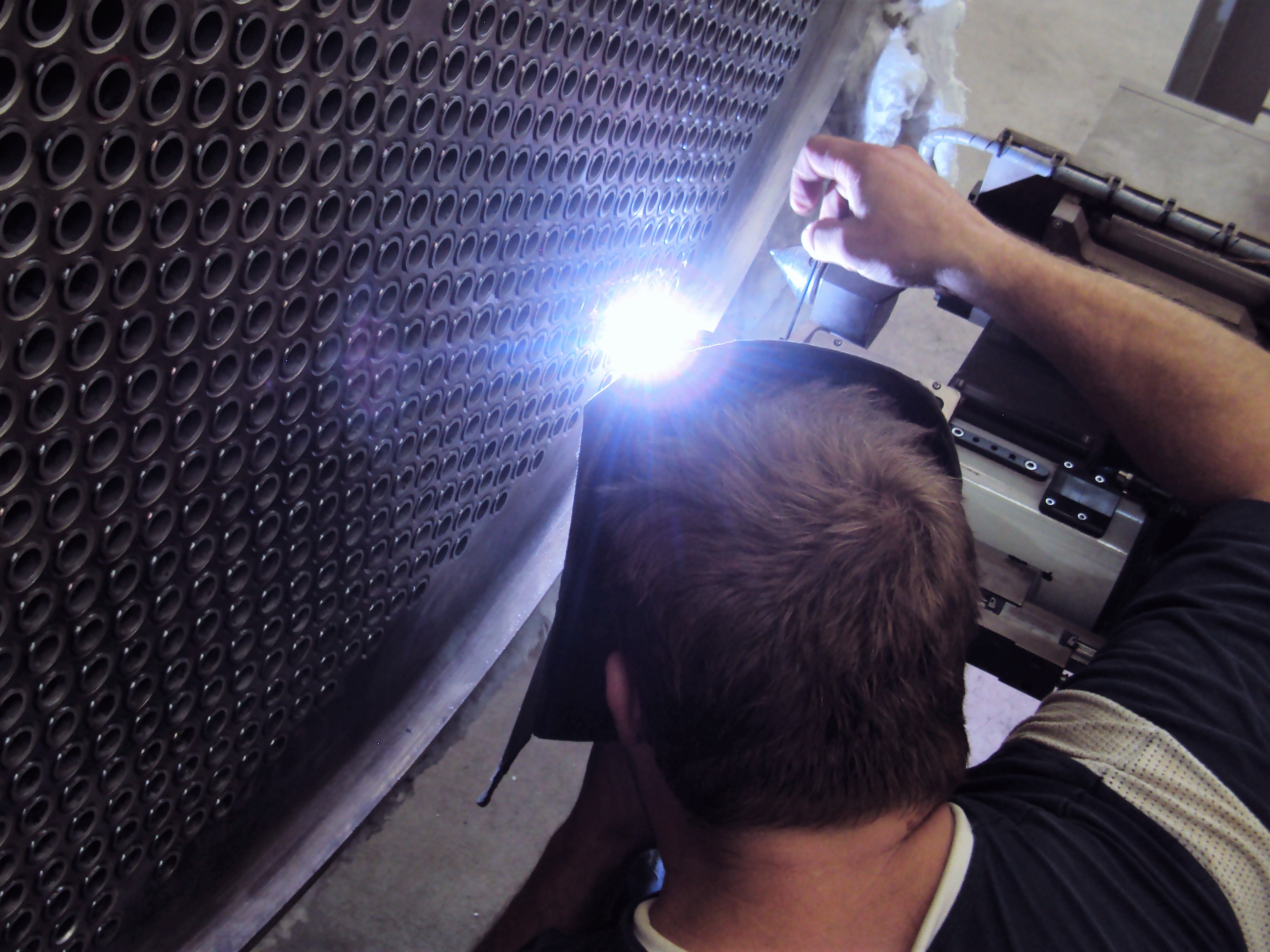

- Tube to Tube-sheet Welding

- Manual

- Automatic (TIG)

- Internal Bore Welding – tube welds in the back of the tubesheet, so to become one thing. This technique is especially used in case of crevice corrosion fluid i.e. Styrene, PTA, Ammonia, etc.

Machining:

- Max Drilling machine diameter 4000 mm.

- Lathes up to mm diameter

Lifting capacity:

- 14 OH cranes up to 135,00 tons

- Total lifting with other devices is 200 tons

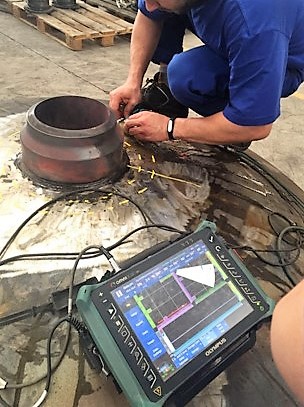

NDT capactity

- X and Gamma Ray bunker available

- UT, MT, PT done in house

Sandblasting & Painting area:

The facility covers an area of more than 200 sq.mt. It is completely closed so that no residual dust (either paint or sand) can disperse in the air.

Titanium Clean Condition Room:

We have a completely segregated clean condition room that works in over pressure with air recycle, where we weld titanium.

AFTERMARKET

Villa Scambiatori can supply replacement spare parts for installed equipment, shipping quickly from our headquarter to whatever location worldwide.

Working closely with the client and our selected sub-suppliers network, we can provide replacement bundles and complete equipment with a very quick delivery, just for shutdowns and turnarounds.